GA Telesis is tucked away just west of Interstate 95, alongside Fort Lauderdale Executive Airport, where the company has its headquarters and a 100,000-square-foot warehouse stocked with aircraft parts.

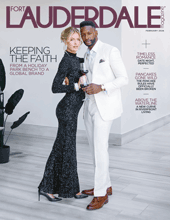

“A lot of times, until people come to our operation and see how big it is, they just don’t realize how big a company we are,” president, CEO and co-founder Abdol Moabery says of a company that maintains, repairs, overhauls and distributes aircraft parts around the world with a far-flung network of locations from Helsinki to Istanbul to Beijing. Among other items in inventory at the company’s Fort Lauderdale warehouse, “we probably have a dozen jet engines sitting here that are waiting for airlines that might need them, spare engines for when they have an airplane breakdown,” Moabery says.

GA Telesis has 250 of its 500 employees stationed in Fort Lauderdale, including skilled mechanics making up to $50 an hour. The company’s major customers in North America are American Airlines, Delta Air Lines, United Airlines, JetBlue, FedEx and UPS. Moabery says the company’s revenues have been rising about 30 percent a year, thanks in part to business acquisitions. “We will hit about $400 million this year,” he says.

GA Telesis is part of a large but low-key cluster of aerospace companies in Broward County. While the Fort Lauderdale area is widely known for its connection to water-based transportation, “the yachting capital of the world” also has deep ties to the aerospace industry thanks in large part to a legacy of talent and a central location within a booming region. Air Show5.png

In 2015, Florida ranked as the best state for aerospace companies, according to a survey by professional services firm PricewaterhouseCoopers. It was the second consecutive year the state was ranked first. Taxes, operating costs and educational institutions were among the factors that sustained the top PwC ranking for Florida. But in South Florida, human capital is arguably the most important asset of the aerospace industry.

“What we have here in South Florida is a talent base that’s unparalleled,” Moabery says. His company is looking for more talent as it prepares to diversify into aircraft parts manufacturing by early 2017 – perhaps at a location in Fort Lauderdale. “Our eyes are right here on Fort Lauderdale,” he says. “It’s the next evolution of our business.”

Worldwide Reputation

South Florida’s deep pool of aerospace talent is a legacy of the area’s history as an aviation hub and the former home of the old Pan Am and Eastern airlines. Those airlines are long gone, but they left behind a large work force skilled in aircraft maintenance, repair and overhaul.

“This area is generally not a design center for new aircraft production. But it is a hub for maintenance activity,” says Victor Mendelson, co-president along with brother Eric of Hollywood-based parts supplier Heico Corporation, the biggest aerospace company by revenue in Broward County. “It traces that heritage back to Eastern Airlines and its headquarters here. Eastern had a big maintenance base here. Pan Am had a big maintenance base here. So there have been a number of spinoff businesses from Eastern and Pan Am people over the years.”

The industry here looks differen from the industry in other, more well-known aerospace hubs such as Seattle.

“This area is not necessarily going to get an Airbus manufacturing facility or Boeing or something like that,” says David Coddington, vice president of business development of the Greater FortLauderdale Alliance. “That’s not the niche where we’re strong. We’re very strong on the maintenance and repair side.

“South Florida is known around the world within that industry for the quality and integrity of the work force.”

South Florida’s sunny weather gives the area an advantage in attracting aerospace companies and other types. So does the area’s location in the eastern time zone. “In the same eight-hour workday, you can talk to customers on four continents,” Coddington says.

CTS Jet Engines, for example, is one of the Broward companies doing that type of work, known in the aerospace industry as “MRO” – maintenance, repair and overhaul. Like many of Broward’s obscure aerospace companies, CTS is hardly a landmark at its location, south of downtown Fort Lauderdale along West State Road 84, an area best-known for Lester’s Diner.

There’s also a lot cooking at the nearby CTS facility, a fix-it station for jet engines. “Engines come in and get overhauled,” Coddington says. “They’ve got a laser grinder at that facility. If a bird hits an engine or a power plant, they break them down. A lot of it is for cargo planes.”

Beyond Fort Lauderdale, aerospace companies also have rooted in other parts of Broward, notably the county’s southwest corner. There are about 25 aviation and aerospace companies in Miramar alone, Coddington says. “Miramar’s got a great cluster,” he says, citing its central location in South Florida. In addition to drawing from Broward’s talent pool, he says, “the work force can come up from Miami on I-75. You can also pull from Palm Beach County.”

There is ample aerospace talent to pull from both north and south of the Broward line.

The Business Development Board, the economic development agency of Palm Beach County, reports that the county has 639 businesses in aviation, aerospace and engineering, with more than 20,000 employees. Prominent among those businesses is B/E Aerospace, the world’s largest manufacturer of seats and other passenger-cabin interior products for jet aircraft. Sikorsky Aircraft Corporation manufactures the U.S. Army’s UH-60M BlackHawk helicopter Bee Line Highway in Jupiter. Pratt & Whitney manufactures jet engines at a West Palm Beach plant that opened in June 2014. Lockheed Martin also has a presence in Palm Beach County.

20,000 employees. Prominent among those businesses is B/E Aerospace, the world’s largest manufacturer of seats and other passenger-cabin interior products for jet aircraft. Sikorsky Aircraft Corporation manufactures the U.S. Army’s UH-60M BlackHawk helicopter Bee Line Highway in Jupiter. Pratt & Whitney manufactures jet engines at a West Palm Beach plant that opened in June 2014. Lockheed Martin also has a presence in Palm Beach County.

The Beacon Council, the economic development agency of Miami-Dade County, reports that the county’s aviation industry spans 466 companies with 21,563 employees making $71,740 a year on average. The county’s top employers in the aviation sector include such companies as AAR Aircraft Maintenance, Boeing Flight Services and the Airbus Americas Training Center. Among cities nationwide, Miami has one of the largest clusters of FAA-approved flight simulators for pilot training.

Pilot training extends to the collegiate level in Broward, where Broward College has degree programs for students who want to become aircraft maintenance specialists or certified pilots. People trained to fly often find ancillary work in aircraft component distribution or maintenance because they have “an extreme amount of knowledge about airplanes,” says Moabery, the CEO of GA Telesis.

“A lot of pilots, while they’re looking for a job, they come into our business and train, and some of them end up staying,” he says. “The lowest trainee who comes in off the street and doesn’t know anything will get somewhere between $32,000 and $38,000 to start.”

Moabery, a graduate of Florida Atlantic University, says his company recruits from an array of higher education institutions including Broward College, FAU, Nova Southeastern University and the Fort Lauderdale campus of Embry-Riddle Aeronautical University, which is based in Daytona Beach.

Location, Location, Location

Founded in 2002, GA Telesis spent its first year and a half in Miami before relocating to Fort Lauderdale. “Principally the reason for moving was, I wanted to draw talent from all three counties. Fort Lauderdale is sort of smack dab in the middle of Palm Beach and Dade,” Moabery says. “The central location is fantastic.”

Mario Catalano, co-owner of 1st Choice Aerospace in Miramar, agrees that the city’s attractions include its central location in South Florida. His company specializes in repairs of such aircraft components as pneumatics, crew seats and fuel systems. Some of the owners of 1st Choice have a similar business in Kentucky, but they chose in 2014 to launch 1st Choice in South Florida.

“South Florida is kind of a hotbed for aviation; it’s got a really nice talent pool of experienced aviation people. That was one of the reasons,” Catalano says. “You can ship to anywhere in the world. It has got good proximity to South America. There’s also a lot of aviation companies down here that are customers and suppliers for us.”

Earlier this spring, the 1st Choice workforce in Miramar had grown to 58 and three additional hires were pending. Most of the new hires are technicians with hands-on experience in aircraft component repairs. “That doesn’t mean we don’t train,” Catalano says, “because we always mix in people we can train with people who have experience.”

Earlier this spring, the 1st Choice workforce in Miramar had grown to 58 and three additional hires were pending. Most of the new hires are technicians with hands-on experience in aircraft component repairs. “That doesn’t mean we don’t train,” Catalano says, “because we always mix in people we can train with people who have experience.”

Any aerospace company in Broward would be fortunate to grow to the size of Hollywood-based Heico.

Publicly held Heico rang up net sales of $1.18 billion in its last fiscal year, the third consecutive year that net sales topped $1 billion. The company’s flight support group and electronic technologies group supply airlines around the world from Heico locations throughout the United States and in 10 foreign countries: Canada, China, France, India, Laos, Korea, Netherlands, Singapore, Thailand and the United Kingdom.

Several hundred of Heico’s 4,600 employees around the world work in Broward. “We’re growing, so the head count will increase,” says Victor Mendelson, the Heico co-president. Heico has a 147,000-square-foot building on Taft Street in west Hollywood that serves as the corporate headquarters and a manufacturing facility cranking out aircraft parts. “It’s mostly hot-section components, the hot part of the plane,” Mendelson says. “It’s metal-working, machining and milling as well as sheet metal fabrication. The place looks like a big warehouse, but it isn’t.”

A couple of aerospace entrepreneurs in Broward have joined the Heico family since the late 2000s. The founders of Blue Aerospace in Sunrise and Sunshine Aviation in Miramar sold their businesses to Heico and continue to run them under their original names.

A Heico business unit since 2008, Sunshine Aviation repairs and overhauls avionic sub-systems for aircraft including total collision avoidance systems, which help pilots avoid mid-air collisions.

Blue Aerospace, part of Heico since 2010, distributes parts for military planes, including F-16 fighter jets and C-130 freighter aircraft, owned by foreign governments allied with the United States – “the kinds of planes that started out in the U.S. fleet and then, over time, became more prevalent in foreign fleets,” Mendelson says.

All these wide-ranging businesses have built a broad community of South Floridians with personal connections to the aerospace industry. “This area is so aerospace-driven, from Palm Beach down to Miami,” says Moabary, the chief executive at GA Telesis. “You always meet someone who is one degree of separation removed from an aerospace company.”

He recalls an airline clerk at a check-in counter addressing him by his name before he handed his passport to her. “I said, ‘How did you know my name?’ She said, ‘I know exactly who you are: My niece works for you.’”