Warehouse office lobbies don’t normally smell this good.

Walk through the front door of Old Florida Lumber Company and you’re immediately hit with the scent of, well, old Florida lumber. It helps that there’s so much of the stuff around.

The headquarters, just off Andrews Avenue and State Road 84, offers several floors, warehouse space and a large outdoor area, but even with all that, there’s wood everywhere. Various logs and cuts are piled and stacked in the front room; a large wooden door leans against the far wall.

Pieces are labeled with printed descriptions. “RECLAIMED OLD GROWTH WHITE PINE, Rough Sawn, Mixed Grade” reads one. “RECLAIMED OLD GROWTH DOUGLAS FIR, Rough Sawn, Select Grade” reads another. Occasionally, they lean towards the poetic – some OLD GROWTH SINKER CYPRESS is said to have “Solid Heart, Figurative Grain.”

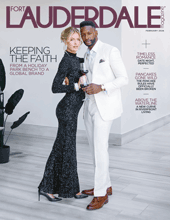

In an office beyond the front desk (made of wood, naturally), Randy Shropshire is on the phone, going over details for a big project that’s currently underway. These are busy times for Randy, a licensed general contractor and mason who owns Old Florida Lumber with Cathy, his wife.

Over several decades, the Shropshires have built this reclaimed wood business from a small sideline into a booming career. Since Randy first got into business in the early 1980s, South Florida has changed as well. Back then, for example, Sailboat Bend was an unfashionable neighborhood with cheap rents and a high crime rate. Today it’s a historic district, and historic Dade pine homes, like the old wood homes elsewhere in Broward, are in demand.

It’s a good time to be an old-wood guy.

“There’s more and more people interested in it,” Cathy says. “They’re incorporating it in big and small ways for their projects.”

That’s not to say these old Floridian woods are easy to use, or for everybody. Dade pine is heavy and thick; pick up a softball-sized piece and you’ll be surprised by something that feels more like a bowling ball. The wood is scarce and the work to get it ready for reuse is labor-intensive. A lot of mill shops hate the stuff.

They “don’t want to deal with it,” Randy says. Resin in Dade pine gums up tools and blades. It works better with specialist, heavy-duty tools – and the sort of know-how that comes with experience. “We were challenged by it,” Randy says. “And we mastered it.”

It’s a hard-earned mastery, learned over many years. Randy worked on his first wood house not long after graduating from South Broward High School. He went with his father and brother to North Carolina to find barn wood for a family friend here who was working with influential South Florida architect Dan Duckham on an impressive wood house.

“He was way ahead of his time,” Randy says of the family friend. “That’s where I really got into it – salvaging the wood with my father and brother. We didn’t really know what we were doing – just getting everything we could get our hands on.”

Later when he started working as a contractor, he’d sometimes find old wood on jobs. “He realized it was great wood,” Cathy says, “and he started collecting the old wood.”

Back then, if somebody with something like an old Dade pine home wanted an addition that was in keeping with the rest of the house, they were going to struggle.

“In those early years, the availability was just not there to go find it or buy it to do renovations or additions on homes of that era,” Randy says. “There wasn’t any material available that you could go buy anywhere. It was real special.

“As you would go, you’d collect a little bit more. It wasn’t like you could get a lot of it at any one time.”

He built a reputation as a skilled craftsman with older structures. One early project involved rebuilding the Stranahan House fireplace.

As the business grew, the side-project to general contracting became a full-time role. The business moved into its current location nearly a decade ago – just at the start of the recession, which caused some worry. But the resurgence of old homes and reclaimed wood was underway, and Randy’s work remained in demand.

Today, Old Florida Lumber’s handiwork can be seen in a number of restaurant and retail spaces as well as in private homes. Randy’s done work for local Whole Foods stores and Himmarshee bar and grill Tarpon Bend Food and Tackle, to name just two.

The Shropshires have also used the products themselves, once taking six years to build themselves a home in Parkland out of reclaimed wood. They’ve since sold the home, but it was an experience.

“We had a journey – a dream of building a home out of the same product we like to salvage,” Randy says.

Big, challenging projects are their focus now. Randy’s done smaller projects in the past – a single table, a bookcase – but today the Shropshires are trying to aim more towards large-scale work. Randy prefers to deal directly with contractors and designers when possible.

Big, challenging projects are their focus now. Randy’s done smaller projects in the past – a single table, a bookcase – but today the Shropshires are trying to aim more towards large-scale work. Randy prefers to deal directly with contractors and designers when possible.

“We’ve been involved with multimillion-dollar homes that have a lot of reclaimed wood in them,” he says. “Most of our work is not local. Most of it’s shipped out of the area.”

For anyone thinking of using old Florida wood in their home, Randy has words of advice and warning.

“Our material is extremely expensive – more so than any new material you could buy,” he says. “Dade pine is hard to work with – it’s super hard and heavy and hard to get the nails out of. It’s not really for the average homeowner to come in and say I want to buy some Dade pine flooring or cypress beams. The value doesn’t happen until you do all the processing. Until it’s really completely fumigated, metal detected, weighed, processed – the value added is in that whole process.

“It’s been a learned process with all the years of experience. There’s a lot of satisfaction in it.”